Services

Operation

Our Operation services provide comprehensive support for the daily operation of wind farms – from continuous monitoring and performance optimization to data-driven decision support and the management of administrative and security processes.

- Daily operation and monitoring

- Power Curve Validation

- Remote monitoring and control

- Condition monitoring and decision support

- Administration and documentation

- Security and compliance

- Coordination and liaison

Preventive maintenance

Preventive maintenance ensures the continuous and safe operation of wind turbines through regular, planned interventions. Our service includes the inspection of mechanical, electrical, and control systems in accordance with OEM specifications. Our goal is to prevent malfunctions, extend the service life of equipment, and optimize production.

- Time-based and operating hour-based maintenance

- Inspections in accordance with manufacturer (OEM) specifications

- Mechanical, electrical, and control system inspections

- Lubrication, adjustment, and cleaning tasks

Corrective maintenance

Corrective maintenance ensures rapid intervention in the event of unexpected failures, minimizing downtime. Our experienced specialists locate and rectify faults on site, replacing parts if necessary. Our goal is to restore production quickly and maintain long-term operational reliability.

- Fault localization and troubleshooting

- Mechanical and electrical repairs

- Parts replacement and on-site interventions

- Emergency call-outs and troubleshooting

Predictive maintenance

Predictive maintenance is based on the analysis of IoT and condition monitoring data, identifying faults before they occur. Monitoring trends and anomalies enables the planning of optimal maintenance interventions. This significantly reduces unexpected costs and maximizes equipment availability.

- Analysis of condition monitoring (CMS, IoT)

- Identification of trends and early signs of faults

- Optimal timing of interventions

- Reduction of maintenance costs and downtime

Parts management and logistics

Parts management ensures that critical spare parts are always available for quick maintenance. We coordinate suppliers and optimize logistics processes. This minimizes downtime and enables a quick response to any intervention.

- Spare parts management and inventory tracking

- Coordination of OEM and alternative suppliers

- Support for logistics processes

- Ensuring availability of critical parts

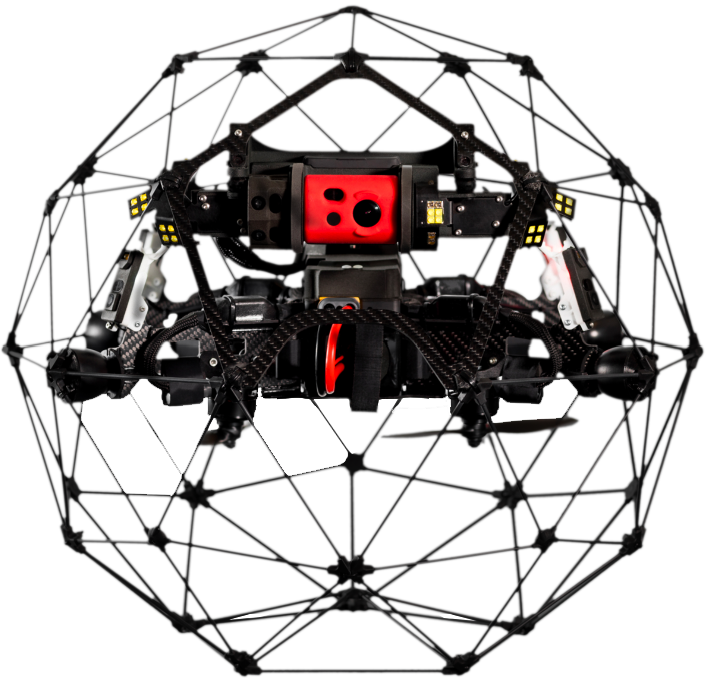

Inspection

The purpose of rotor blade and structural inspections is to comprehensively assess the condition of critical components of wind turbines. We thoroughly inspect the surface and internal structure of rotor blades, as well as the structural components of the tower and nacelle to ensure safe and efficient operation. Based on our findings, we provide our customers with well-founded maintenance and repair recommendations. All our inspections are carried out using drones, making them safer, faster, and cheaper. Advanced AI-driven data automation.

- Internal inspection

- External inspection

- Thermograph inspection

- Lightning Protection System (LPS) inspection

- Tower wall tickness inspection

- ADT inspection

Smart turbines

IoT-based condition monitoring and maintenance support tool Our newly developed IoT sensor data collection tool continuously monitors the condition of the main components of wind turbines.

By analyzing the collected data, the system makes intelligent, well-founded maintenance recommendations, thus promoting predictive maintenance and avoiding unexpected failures. The device can be integrated into existing SCADA and O&M systems, increasing equipment availability and long-term operational reliability.

- Spare parts management and inventory tracking

- Coordination of OEM and alternative suppliers

- Support for logistics processes

- Ensuring availability of critical parts

Key features:

- Real-time data collection on key components: drive, generator, main bearing, rotor

- Vibration, temperature and load measurements

- Data analysis to support predictive maintenance

- Automatic generation of alerts and maintenance recommendations

- Can be integrated into existing SCADA and O&M systems

Advantages:

- Reduces losses due to unexpected downtime

- Optimizes maintenance costs and timing

- Increases equipment lifespan and reliability

- Provides decision support at the O&M and owner levels

Learn more about our services:

Contacts

Address

Veder utca 10,1035 BUDAPEST, HUNGARY